What are the classifications of electrical wires?

Dec 11, 2025

Electrical wires are the fundamental carriers of electrical energy transmission and information transmission. They can be classified in various ways, mainly based on their application, conductor material, insulation material, voltage level, and special properties. The following is a detailed classification explanation:

I. Classification by Application

1. Power Cables

Bare conductors/bare wires: Without insulation, such as aluminum stranded wire and steel-cored aluminum stranded wire used for overhead power transmission.

Insulated wires: With insulation, used for fixed wiring or equipment connections, such as BV and BVR wires commonly used in home decoration.

Power cables: With insulation and multiple layers of protection (such as armor and sheath), used for underground laying or complex environments, such as YJV and VV cables.

2. Electrical Equipment Wires and Cables

General-purpose wires: Connecting electrical appliances, instruments, etc., such as RVV sheathed wire (commonly known as "flexible wire").

Special-purpose cables: Used for specific equipment, such as low-voltage automotive wires, welding machine cables, and elevator cables.

3. Communication Cables: Transmit electrical or optical signals, such as telephone lines (HYA type), network cables (twisted pair Cat5e/Cat6), coaxial cables (for television signals), and fiber optic cables.

4. Electromagnetic Wires (Winding Wires): Used for winding coils in electromagnetic equipment such as motors and transformers, such as enameled wire and silk-covered wire.

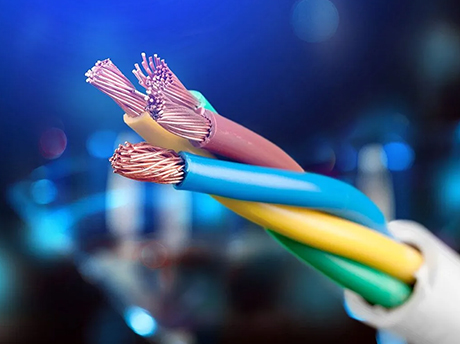

II. Classification by Conductor Material

1. Copper Core Wire: High conductivity, good ductility, and corrosion resistance; the most commonly used conductor, such as BV (copper core PVC insulated wire).

2. Aluminum Core Wire: Lightweight and low cost, but with poor conductivity and prone to oxidation; mostly used for overhead power transmission or low-voltage power distribution, such as BLV (aluminum core PVC insulated wire).

3. Alloy Wires: Such as copper-clad aluminum wire and aluminum alloy wire, balancing performance and cost, used in specific applications.

4. Other Materials: Such as silver wire (for high-frequency precision instruments) and tin-plated copper wire (for corrosion resistance).

III. Classification by Insulation Material

1. Plastic Insulated Wires

PVC (Polyvinyl Chloride) Insulation: Commonly used, low cost, acid and alkali resistant, such as BV and BVR.

PE (Polyethylene) Insulation: Good high-frequency characteristics, used in communication cables.

XLPE (Cross-linked Polyethylene) Insulation: Good heat resistance, used in power cables (such as YJV).

2. Rubber Insulated Wires: Soft, cold-resistant, and wear-resistant, suitable for mobile equipment, such as YZ type rubber-sheathed cables.

3. Mineral Insulated Cables: Such as MI cables (copper core magnesium oxide insulation), extremely fire-resistant, used in fire protection systems and high-temperature environments.

4. Special Insulation Materials: Silicone rubber (high temperature resistant), fluoroplastics (corrosion resistant), etc.

IV. Classification by Voltage Rating

1. Low-Voltage Wires and Cables: AC voltage ≤ 1kV, such as BV and RVV wires for household electricity (220V/380V).

2. Medium-Voltage Cables: AC voltage 6kV~35kV, used in urban power distribution networks and industrial power. 3. High-voltage cables: AC voltage ≥110kV, used for long-distance power transmission.

V. Classification by stiffness/flexibility

1. Solid wire (single-strand wire): such as BV wire, a single solid copper core, high stiffness, suitable for fixed wiring.

2. Flexible wire (multi-strand stranded wire): such as BVR wire, RVV wire, multiple fine copper wires twisted together, good flexibility, suitable for mobile equipment or complex bends.

VI. Classification by fire resistance/fire-resistant properties

1. Flame-retardant wire (ZR type): Flame spread is controllable, such as ZR-BV, ZR-YJV.

2. Fire-resistant wire (NH type): Can maintain power for a period of time in a flame, such as NH-BV (mineral insulation or special coating).

3. Halogen-free low-smoke type (WD type): Low smoke density and no toxic halogen gases during combustion, such as WDZ-YJY, used in subways, hospitals, and other densely populated areas.

VII. Classification by National Standards/Certifications

1. National Standard Wire: Complies with national standards (e.g., GB/T), conductor cross-sectional area, insulation thickness, and other parameters meet standards, ensuring high safety.

2. Non-standard Wire: May be made with substandard materials to reduce costs (e.g., insufficient cross-sectional area), posing safety hazards.

3. International Standard Wire: Complies with IEC (International Electrotechnical Commission), UL (USA), CE (EU), VDE (Germany), etc., used for export or specific projects.

Examples of Commonly Used Home Wiring

BV Wire: Single-core hard copper wire, suitable for fixed wiring such as concealed installation in walls.

BVR Wire: Multi-strand soft copper wire, suitable for wiring in distribution boxes that require bending.

RVV Sheathed Wire: Multi-core soft wire with an outer sheath, used for electrical power cords, temporary sockets, etc.

Precautions for Choosing Wires

1. Clarify the purpose: Choose hard wire (BV) for fixed wiring, and soft wire (BVR/RVV) for mobile equipment.

2. Matching Current Carrying Capacity: Select a cross-sectional area sufficient for the appliance's power (e.g., 1.5mm² for lighting, 2.5mm² for sockets, 4mm² for air conditioning).

3. Using National Standard Products: Avoid using non-standard cables; ensure insulation thickness and conductor material meet standards.

4. Environmental Adaptability: Use waterproof cables for humid environments, heat-resistant cables for high-temperature environments, and fire-resistant cables for fire protection systems.

Read More